Description

Description:

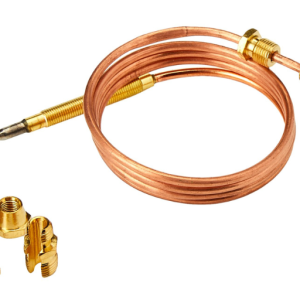

Tubular heating elements are widely used in heating applications due to their versatility, durability, and ease of manufacturing. They are commonly used in industrial and domestic appliances like water heaters, ovens, air conditioning units, and even industrial machinery. The heating element is typically made of high-resistance metal (such as nickel-chromium (NiCr) or iron), and it is housed in a tubular metal sheath that helps to distribute the heat evenly.

Below are the key specifications and features for Tubular Heating Elements designed for different voltage levels: 110V, 220V, and 480V.

Key Features:

-

Voltage Rating:

- 110V: Common in residential applications, particularly in the United States.

- 220V: Common in European and Asian residential and industrial applications.

- 480V: Used in heavy industrial applications, especially for high-power equipment and large-scale heating applications.

-

Power Rating (Wattage):

- The power rating of a heating element determines how much heat it can generate. It’s generally measured in watts (W

Specifications:

-

Length and Diameter:

- Length: The length of the heating element is variable and typically depends on the power rating and intended use. For example, a standard home water heater might have a tubular element that’s about 300mm to 500mm long.

- Diameter: Common diameters for these elements are 6mm, 8mm, 10mm, and larger. A larger diameter generally allows for more power, as it accommodates a thicker coil.

-

Temperature Rating:

- Operating Temperature: Tubular heating elements can operate at temperatures between 200°C to 800°C (depending on the material and voltage).

- Max Surface Temperature: The surface temperature of the element is designed to be in the range of 500°C to 700°C, though the specific temperature will depend on the wattage and usage conditions.

Reviews

There are no reviews yet.